Maintenance

Based on the inspection carried out in advance or damage reports by third parties, maintenances are carried out in connection with MAURER-related components. The time required for the maintenance is significantly shorter than for a new structure. The most common maintenance measures are presented here as examples.

Other solutions can be coordinated with our team of specialists.

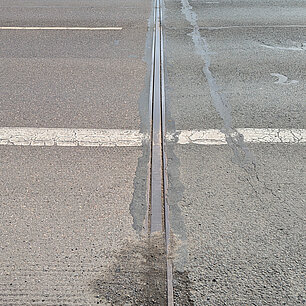

Maintenance of expansion joints

Expansion joints can be maintained by regularly replacing parts that are subject to wear, such as bearings, springs and sealing profiles. If the damage to the expansion joints is so extensive that the load-bearing capacity is compromised, the expansion joints can be modified.

Maintenance of a D1 strip joint

Maintenance may be necessary if the edge profiles are so badly damaged that the sealing profiles can no longer be accommodated in a watertight manner, or if the joint gap is too narrow to allow replacement of the sealing profile. A maintenance can also be carried out for technical or economic reasons.

The expansion joint in need of maintenance can be completely replaced with a new expansion joint. In this case a D1 with a new edge claw profile (variant: hybrid claw profile). The advantage of a hybrid claw profile is that it is corrosion-resistant in the area of the sealing profile and in the weathered area.

Advantages:

- Preservation of the edge profiles embedded in concrete

- No concrete or reinforcement work required

- Short maintenance time compared to a new structure, easy to integrate into asphalt roadwork

- Improved corrosion resistance

- By using MAURER Betoflex®, no sealing or asphalt work by subcontractors is necessary

Expose the expansion joint on both sides. The claw profile is cut off at the height of the isolation flange.

Old existing structure

The substructure is provided with new corrosion protection. A hybrid claw profile is placed on the existing structure. The blue area is filled with Betoflex® (polymer concrete). The new sealing profile is installed.

D1 expansion joint after the maintenance

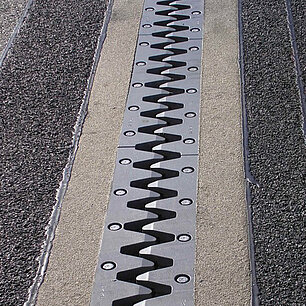

Reconstruction of a two to a strip joint

In existing structures, the creep and shrinkage of the concrete has almost entirely subsided. This results in reduced movement of the expansion joint. In most cases, a two-seal expansion joint can be replaced by a strip joint. In this variant, all moving steel and wearing parts (centre beam, bearing, spring, etc.) are completely removed. The existing anchoring also remains in the structure in this case.

Expose the expansion joint on both sides. The edge profiles are cut off at the height of the anchoring legs.

Old existing material

The substructure is provided with new corrosion protection. A claw profile is placed on the existing structure. The blue area is filled with Betoflex® (polymer concrete). The new sealing profile is installed.

D1 expansion joint after the maintenance

Maintenance option, use of XL1 strip joint

Expose the expansion joint on both sides. The edge profiles are cut off at the height of the anchoring legs.

Old existing material

The substructure is provided with new corrosion protection. The XL1 edge profiles are installed on the existing structure. The new sealing profile is installed. The XL1 panels are bolted to the existing structure. The blue area is filled with Betoflex® (polymer concrete).

XL1 expansion joint after the maintenance

Maintenance option, use of XW1 strip joint

Expose the expansion joint on both sides. The edge profiles are cut off at the height of the isolating flange.

Old existing structure

The substructure is provided with new corrosion protection. The entire XW1 is installed on the existing structure. The new sealing profile is installed. The blue area is filled with Betoflex® (polymer concrete).

XW1 expansion joint after the maintenance

Reconstruction based on "box in box" system for girder grid expansion joints

For modular expansion joints, a reconstruction based on the "box in box" system can be considered instead of a completely new structure. The new expansion joint is adapted to the geometry of the existing structure on the basis of measurements taken before planning begins. This reconstruction can also be carried out in several construction phases with only one side closed while the flow of traffic is maintained.

Maintenance of swivel joist expansion joint, replacement of centre beam/support bar assembly

Swivel joist expansion joints are also used for larger, modular expansion joints. The geometric control is based on diagonally arranged support bars. If a maintenance is necessary, all fatigue-relevant components can be replaced. To do this, the centre beam assembly, including all bearing elements, is replaced.

- Preservation of the anchored edge profiles and support bar boxes embedded in concrete

- Minimal concrete, steming and reinforcement work required

- Short repair time compared to a new installation

This maintenance option can also be used for girder grid expansion joints. Unlike the "box in box" variant, the new transition structure is installed without new support bar boxes. The new support bars are installed in the existing support bar boxes.

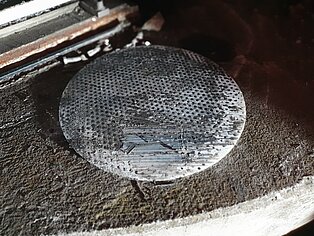

Maintenance and replacement of bridge bearings

One criterion for assessing an existing bearing is, for example, the sliding gap in pot and spherical bearings. In the past, the sliding material PTFE was used, which has a significantly lower wear resistance than the MSM® sliding material used by MAURER for bearings. If a bearing requires refitting due to the sliding gap being too small, only the sliding material need be replaced while the existing bearing is retained. The MSM® sliding material is used as a replacement.