Restraint devices

MAURER restraint devices can be used separately or in conjunction with bearings. They permanently or temporarily limit or block horizontal movements of the bridge superstructure relative to the substructure in one or two directions.

- Restraint during normal and frequent service load cases with or without load distribution

- Restraint during earthquakes with or without load distribution

MAURER restraint device (permanent): HK/HKE

MAURER restraint device (temporary): MSTU/MSTL

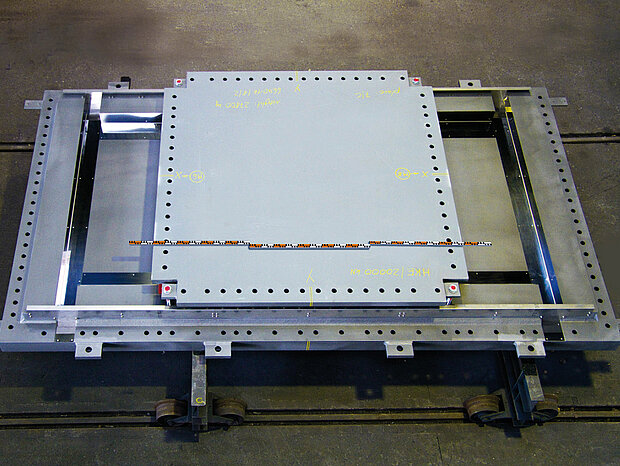

Permanent restraint device - HK/HKE

- Project-specific versions for permanent force transmission

- Fatigue-resistant design

- Retaining the deck horizontally in X and Y direction (HK)

- Retaining the structure horizontally in one direction, in which case it is capable of moving in the other direction (HKE)

- Horizontal forces > 25 MN

- See also guide bearings

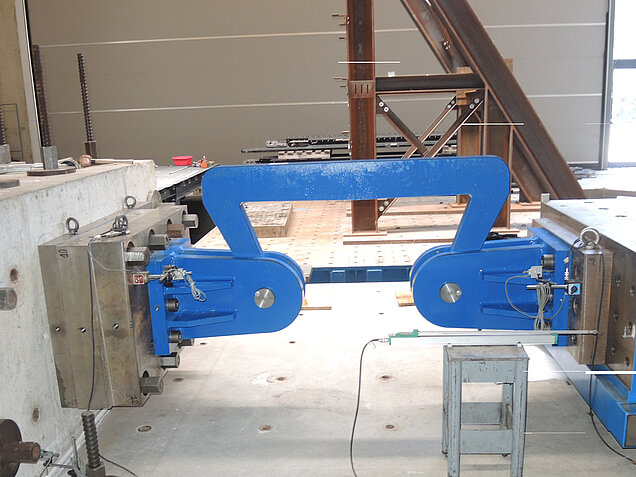

Temporary restraint devices – MSTU/MSTL Shock Transmitter Unit

Restraint systems can also be designed so that horizontal thermal motion is possible without resistance and that movement is only stopped in the event of corresponding shock or pulse loads. These devices are hydraulic and are called shock transmitters.

In conformance with EN 15129, the design force should be increased with a reliability factor gx of 1.5, unless an overload protection system (load limitation) is used, in which case the factor may be reduced to 1.15. In the event of sudden service or seismic loads, the restraint systems with load limiters, called MSTL, can be connected in serial or parallel arrangements. This distributes the loads evenly. The restraint systems without load limiters, called MSTU, can also be used in serial or parallel arrangement. However, possible overload conditions need considered in the preliminary design with a reliability factor gx of 1.5. This is why the MSTUs are larger and more expensive than MSTLs. In addition the structure must be designed for greater forces, makes the MSTL version with load limiters is a better option.

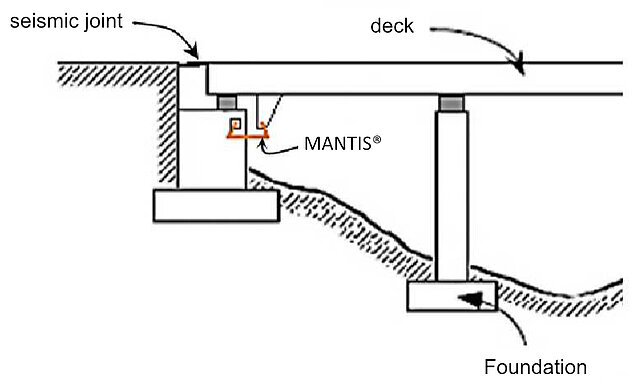

Steel hysteresis dampers - MANTIS®

MANTIS® steel hysteresis dampers have specially formed steel elements that are plastically deformed during earthquakes. The forces occurring in the structural elements are only dependent on the movement. This deformation leads to damping and the steel elements get heated by dissipated energy.